Utilities Industry

Desalination

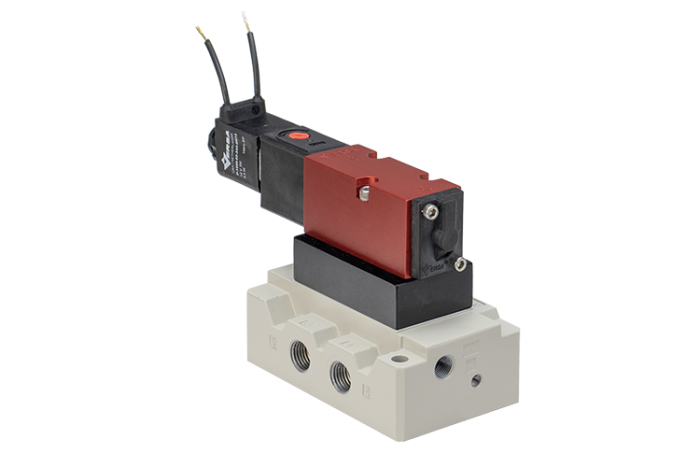

Desalination facilities operate in some of the harshest environments—where salt air, high humidity, and corrosive media put equipment to the test. VERSA’s 316 stainless steel valves are built to withstand these challenges. Engineered for resilience and performance, VERSA offers a full range of corrosion-resistant valves and air preparation systems designed specifically for seawater applications. With global support and a ten-year warranty, VERSA keeps your operations running reliably—no matter how tough the environment.

Key Features

VERSA delivers proven solutions for the toughest challenges in desalination. From intake to distribution, VERSA valves help protect critical systems, reduce downtime, and keep operations running smoothly. Built with durability, precision, and flexibility in mind, VERSA supports your plant’s long-term reliability in even the harshest marine environments.

Corrosion Resistance

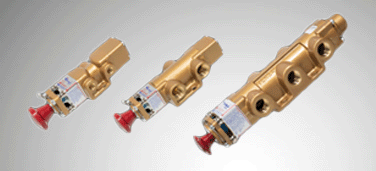

VERSA valves use high-grade materials like 316 stainless steel and marine grade materials to withstand harsh saltwater conditions.

Proven Safety Performance

VERSA provides dependable operation for emergency shutdown and critical controls.

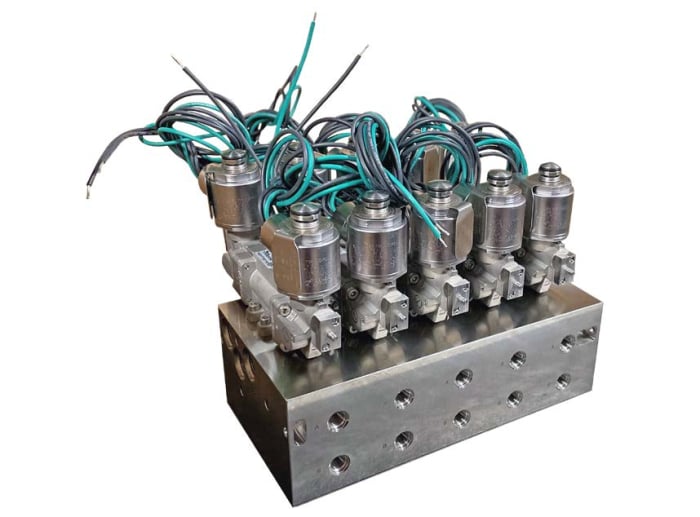

Modular Design

VERSA allows flexible configurations to suit specific plant needs.

Real-World Applications

Pretreatment & Filtration Systems

Desalination plants rely on precise and consistent valve performance to control flow in multimedia, cartridge, and ultrafiltration stages. VERSA valves resist corrosion, ensuring reliability even with high salinity and abrasive contaminants.

Pumping Systems

Critical to the reverse osmosis process, these systems require dependable actuation for pressure regulation and safety. VERSA’s stainless steel valves handle pressure demands and resist pitting and cracking from saltwater exposure.

Brine Management & Discharge

Efficient handling of concentrated brine requires durable components. VERSA’s air prep and control valves maintain smooth operation while minimizing the risk of environmental corrosion or system failure.

Instrument Air & Utility Systems

Desalination plants require reliable pneumatic and utility systems to power valves and automation. VERSA’s robust air preparation units and actuated valves deliver clean, dry air and consistent performance in corrosive coastal environments.

Related Documents

Why Choose VERSA?

Proven Performance in Harsh Environments

VERSA valves are engineered to operate reliably in corrosive and demanding conditions, making them ideal for desalination plants where salt, humidity, and extreme temperatures challenge ordinary components.

Superior Corrosion Resistance

Our 316 stainless steel and marine-grade materials deliver unmatched corrosion protection, making VERSA the preferred choice for saltwater and offshore environments where durability is critical.

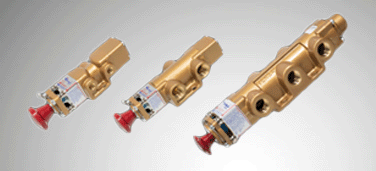

Comprehensive Product Range

We offer a complete portfolio of control valves, solenoid valves, and accessories tailored for desalination plant requirements, supporting every stage from seawater intake to fresh water output.

Certified Quality and Compliance

VERSA products comply with international standards, including CE, ATEX, IECEx, and more, ensuring peace of mind for safety and regulatory compliance in desalination operations.

Related Blogs

Preventing Injury with Pneumatic Lockout Valves

Pneumatic lockout valves are a simple yet critical safeguard that can prevent serious injury or even death during maintenance and repair.

VERSA Solenoids: Globally Certified for Unmatched Performance

Discover how VERSA’s solenoids meet the world’s toughest certifications for safety, reliability, and performance. Trusted worldwide for critical applications.

Built for Real World Reliability

When failure isn’t an option, VERSA valves deliver dependable performance in the world’s toughest conditions—backed by decades of engineering expertise.