Energy Industry

Carbon Capture, Utilization and Storage

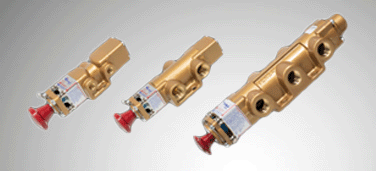

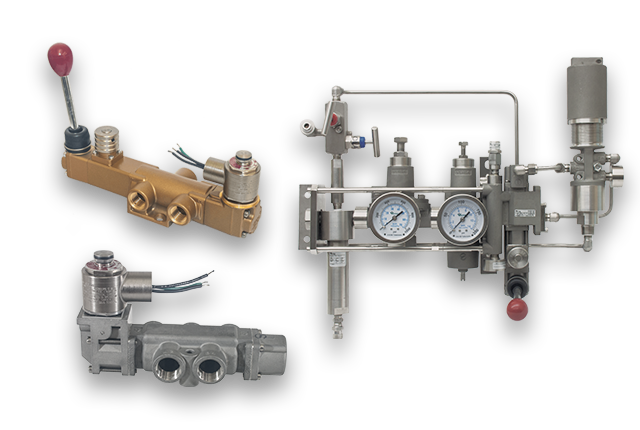

As global industries push toward decarbonization, Carbon Capture, Utilization & Storage (CCUS) has emerged as a vital solution for reducing emissions. VERSA’s rugged valve solutions support every phase of CCUS—from compression and transport to injection and storage—providing control you can count on in high-pressure, corrosive environments. Built for durability and performance, VERSA valves help keep operations safe, compliant, and continuous.

Key Features

VERSA valves are built to meet the demanding conditions of carbon capture systems. From remote field installations to high-pressure process lines, our products deliver reliable performance where it counts. Engineered for durability, safety, and adaptability, VERSA supports every phase of your CCUS operation.

Low-Cycle Reliability

VERSA’s valves, including our PowerShift pilot valves, are engineered for dependable performance in low-cycle emergency shutdown (ESD) applications, ensuring safe and precise actuation when it matters most.

Modular Designs

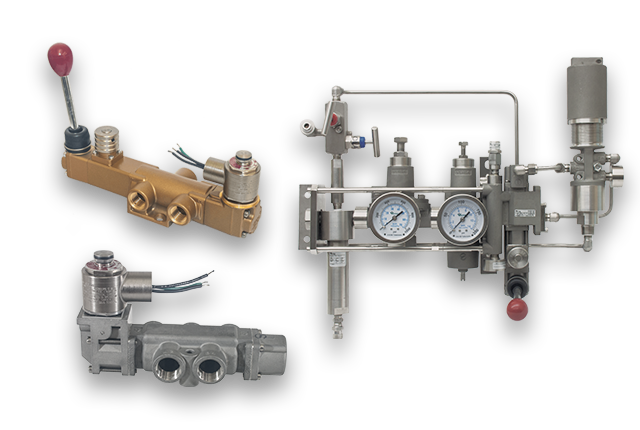

Modular valve options tailored to your specific application requirements—helping engineers design systems that fit both technical needs and operational constraints.

Diagnostic Feedback Integration

Optional position sensors and feedback modules enable real-time system monitoring, improving safety and control across compression, transport, and storage phases.

Real-World Applications

Capture & Separation Units

VERSA valves support gas stream isolation and directional control in amine-based and membrane separation systems. Our precision-engineered components ensure safe handling of CO₂-rich streams under varying conditions.

Compression & Dehydration

In high-pressure CO₂ compression systems, VERSA valves help maintain flow integrity and safety. They perform reliably under extreme temperatures and pressures, making them ideal for booster and dehydration skid packages.

Transport Pipelines

Our valves offer long-life performance in CO₂ pipeline applications, resisting internal corrosion and environmental wear. They support isolation, venting, and emergency shut-off needs along the transport path.

Injection Wells & Storage Sites

VERSA valves are built to perform in remote and hazardous storage environments. They deliver safe, reliable control in subsurface injection systems, where precision and fail-safe operation are critical.

Related Documents

Why Choose VERSA?

Built for Harsh Environments

VERSA valves are designed to operate in high-pressure, corrosive, and remote conditions typical of CCUS sites. Our materials and engineering ensure long-term performance in CO₂-rich applications.

Proven Reliability

With over 75 years of field experience, VERSA’s track record spans oil and gas, power generation, and emerging energy technologies. Our valves are trusted worldwide to deliver consistent performance in mission-critical environments.

Flexible, Field-Tested Designs

Our modular valve platforms adapt to evolving system needs, simplify maintenance, and reduce downtime—backed by components proven in some of the world’s toughest operating conditions.

Support You Can Count On

From technical guidance to quick-turn solutions, VERSA's team works directly with engineers and integrators to ensure your system meets safety and performance goals—on time and on spec.